I haven't owned tons of surfboards. My humble quiver is but three boards; a hand-me-down that I predictably posca-ed a mermaid on, a 6 foot starter board I bought off craigslist in Santa Monica, and an ultra dreamy 5'10" fish that I had custom made from recycled styrofoam, bamboo inlay, and tree sap resin. (Swoon.)

I heard about this technology through my pal Alison Teal who tours the world surfing magical spots and advocating against plastic pollution. She proudly showed me her bright pink board and explained that it is made from recycled styrofoam. With a plastic-free life motto, it always worried me a bit how wasteful my favourite sport seemed. From snapped boards to crazy fumes in the factories, plastic was everywhere and it didn't feel heaps organic.

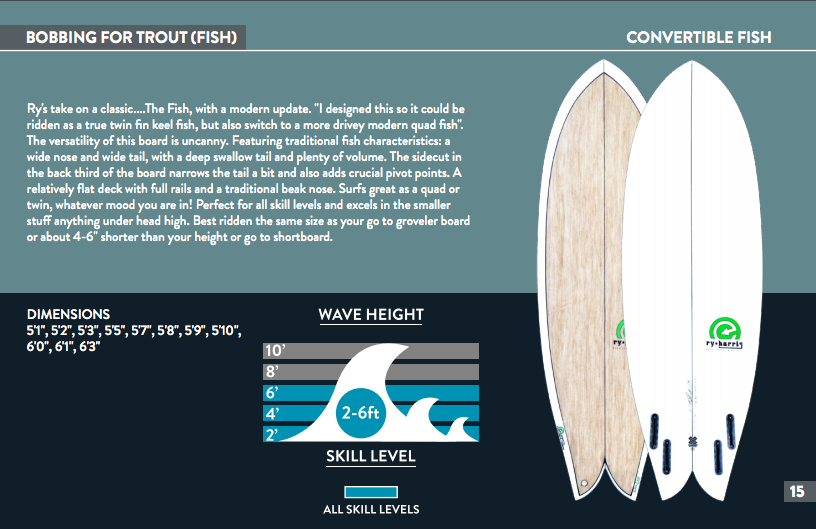

I called up Ryan Harris, who shaped Alison's pink board. Without delay, I braved the standard bumper-to-bumper LA traffic and arrived at his factory to help design my new surfboard. Ryan let me have my say: I wanted light blue with bamboo inlay, a super classic twin-fin fish shape that I could bring to ocean conservation events and inspire people about the recycled foam. With a cheeky look, he said "this isn't going to be a mount on the wall, cutesy board. This is going to be your all-time favourite board. You are going to catch so many waves on this." He made a few quick changes to the design and sent me on my way.

“Stay calm and always trust your shaper.

”

A week later, Ryan had my board. He was headed to the sea, so he dropped it by my house. It was pristine. I laid it in my bed like a newborn baby and stared at it for hours. Running my hands over the super smooth finish. It was perfect.

To this day, I pretty much only surf this board. It's too good. The fish is the most versatile board I have ever played on.

EXTRA-MINI HISTORY OF ECO BOARDS

You walk into most shaping workshops or board factories, and there is an abrasive scent lingering. It's the hectic odour of polyester resin, a carcinogenic, syrupy compound that a shaper will brush onto layered fiberglass cloth to form the board’s hard outer shell. Surfboards have been made with these toxic materials in garages and backyard sheds since the early 1960s!

The basic anatomy of a surfboard is the blank and the shell. The blank is the core; it provides buoyancy. The shell is wrapped around the core. Blanks are traditionally made from polyurethane foam, which emit a fair few toxic gases during manufacture. Like fiberglass and polyester, polyurethane has forever been accepted as #1 from the surfing world.

The industry had a shocker when Clark Foam, the major supplier (a.k.a. monopoly) of low-cost blanks, suddenly shut it's doors in late 2005. NEVER TO OPEN AGAIN. Rumours rippled that it was due to pressure from the Environmental Protection Agency! Righteous, ay? Clark's operation has been under scrutiny due to the toxic nature of polyurethane and the proximity to residential areas. But, the owner, Grubby Clark, had made his multi-millions, so with a bit of a nudge to tone down the toxins, he gave a big "NAH." And shut up shop.

Backyard shapers were panicking everywhere. Low-priced, mass manufactured boards from Asia started to flood the scene. The surfers didn't bite at these "soul-less" boards.

“ It forced the industry to be open-minded.” ”

It was a weird time for surfing. Small time blank manufacturers finally had a shot. Shapers were looking to eco blanks at a time when the supply was so low, they were practically forced to consider the alternatives. Mushroom, cork, algae--it was all seeing salt time.

RECYCLING FOAM

Marko Foam Blanks were the first guys to start recycling styrofoam into surfboards. In 2006, when Clarks' closure let the experimental folk grab a chunk of the market, Marko's reformulation process was being developed and in it's infancy with many stages of R&D. By 2009 the manufacturing process had been perfected.

This innovative technology allows all types of EPS (foam) regrind, not just surfboard scraps, to be made into a high grade, mouldable material and be put back into production again. Marko has also partnered up with Sustainable Surf to help their Ecoboard project which helps people find high performance surfboards with a reduced environmental and toxic impact. Marko is proud to be a part of this amazing process and introduce the first 25% recycled EPS blank.

Collected post-use EPS is put into a mulching machine that breaks down the material to smaller pieces called “re-grind”. Loose re-grind pieces are conveyed into a holding bag and fed down into a machine that compresses the regrind into highly dense rectangular blocks (20pcf). The blocks of recycled EPS are then reprocessed into Envirofoam that is remanufactured into blanks on the same equipment that makes the Virgin EPS blanks. Envirofoam material can be recycled and reprocessed into a usable blank material over and over… and over… and over… again. Envirofoam is an outstanding blank choice for sustainability in the Surfboard Industry.

TREE SAP RESIN

Polyester has long been the standard for surfers who obsess over variations in weight and flexibility; it is ideal for density and workability. But with the influx of material changes, like more premium epoxy resins (which make the board stronger, last longer, thus more sustainable), it was obvious the next step would be more natural resins; effectively moving away from the chem-heavy polyester + polyurthene combo.

Back when Clark Foam was closing and the market was opening, two so-cal brothers were putting their tech degrees to use in the board business. A chemist and an engineer, Rey and Desi Banatao, were experimenting with both shells and the blanks. Their first blanks were made from sugar beet oil; chemically, the beet polymer is almost identical to polyurethane, yet was able to be processed without as many toxins. Rey would also wrap blanks in hemp cloth to enhance flex and feel. This process coloured the boards yellow.

With white poly boards being the go-to for decades, surfers were fairly skeptical. The yellow colouring put many off and the doubt in the look of the board crept into doubt in the performance and durability as well. So, the brothers quit the blank business and stuck to their pine-oil based epoxy resin, now a hugely successful enterprise, Entropy Resins.

The Banatao brothers employ chemistry techniques that require less energy and produce less harmful byproducts, reducing the greenhouse gas emissions from production of their resins by 50% over conventional petroleum based epoxies. Yew.

RYAN JOINS THE ECO BOARD MOVEMENT

When Entropy called it quits on their own line of boards Ry partnered with another eco-shaper, Todd Patterson. In 2011 they opened the world's first full-scale eco-surfboard and stand up paddle board production facility. They dropped their respective labels to create E-Tech Boards and Earth Technologies, a sustainable board building service. (This is when I found Ry and placed my order.)

In late 2015, Todd and Ryan parted ways and shut down E-Tech Boards. From the ashes of E-Tech rose E3 Surf Craft. The glassing business remains Earth Technologies.

E3 also makes a surfboard from 3/4 virgin polystyrene (or styrofoam) and 1/4 recycled polystyrene. It is not 100%, but the recycling of polystyrene is unfortunately extremely uncommon due to how inefficient and expensive it is. I believe any recycling of it is a good step, considering most of it ends up in landfills...FOREVER!

Fack, that's a can of worms, ay.

Only just scratching the surface.

TO BE CONTINUED...

*If you're in California, or willing to drive there, donate your clean styrofoam to Waste to Waves!

SOURCES

- http://www.forbes.com/forbes/2008/0901/058.html

- http://entropyresins.com

- http://e3surfcraft.com/

- http://newfuture.volcom.com/2010/10/the-eco-board-project-interview-entropy-resins/

- http://markofoamblanks.net

- http://www.grindtv.com/surf/6-sustainable-surfboard-alternatives/#9uulVHuTZQ88kEDW.97

- http://www.surfermag.com/blogs/culture/clark-foams-demise-10-years-later-grubby-clark/#sgoaEBXgoKDA86ku.97

- http://www.surfingmagazine.com/news/clark-foam-120505/#EgLxBJjAORcmvzxU.97

- http://www.surfermag.com/features/clarkfoam/#X6SmY6GFiW5S53GO.97

- https://www.youtube.com/watch?v=-Hct-LPLITQ